Berapa lama masa pakai setiap bagian alat pemurni air industri?

Industrial water purifiers play a vital role in many industries, ensuring that water quality meets the standards required for production and operation. However, industrial water purifiers are composed of multiple key parts, each of which has its specific function and service life. Understanding the service life and maintenance cost of these parts is crucial for equipment management and cost control of enterprises.

This article will analyze in detail the service life and maintenance cost of each major part of an industrial water purifier to help readers better understand how to effectively maintain and manage these equipment.

What is the service life of each part of an industrial water purifier?

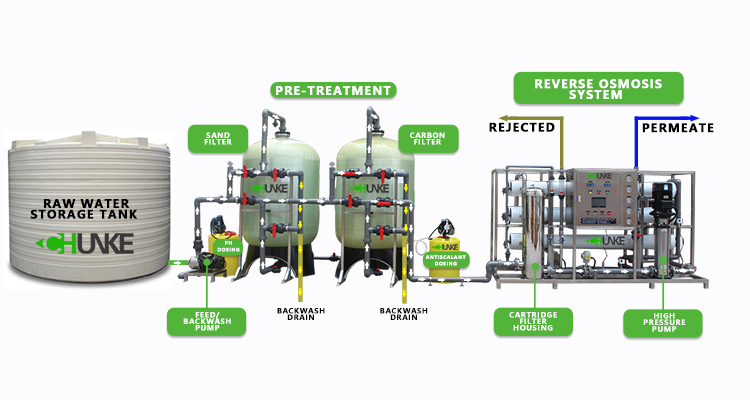

Industrial water purifiers are usually composed of the following main parts: filter element, pump, reverse osmosis membrane (RO membrane), pressure gauge, controller, water storage tank and piping system. The service life of each part varies depending on its material, working environment and frequency of use.

Filter element

The filter element is one of the core components of an industrial water purifier, mainly used to filter impurities, suspended matter and tiny particles in water. Common types of filter elements include activated carbon filter elements, polypropylene (PP) fiber filter elements and ceramic filter elements.

● Activated carbon filter element: Activated carbon filter element is mainly used to absorb pollutants such as chlorine, odor, and organic matter in water. Its service life is usually 6 months to 1 year, depending on the water quality and frequency of use. When the water quality is poor or the frequency of use is high, the life of the filter element will be shortened accordingly.

● Polypropylene fiber filter element: PP filter element is mainly used to remove large particles of impurities in water, such as silt, rust, etc. Its service life is generally 3 to 6 months, depending on the concentration of impurities in the water and the quality of the filter element.

● Ceramic filter element: Ceramic filter element can effectively remove bacteria and microorganisms due to its small pore size. Ceramic filter element has a long service life, usually up to 1 to 2 years, but needs to be cleaned regularly to maintain its filtering effect.

Reverse osmosis membrane (RO membrane)

The reverse osmosis membrane is one of the most critical components in industrial water purifiers. It uses pressure to force water molecules through a semi-permeable membrane to remove pollutants such as dissolved solids, heavy metals, salts and organic matter in the water. The service life of the RO membrane is usually 2 to 3 years, depending on the quality of the inlet water and the effectiveness of the pretreatment system. The life of the RO membrane may be greatly shortened if the influent water quality is poor or pre-treatment is insufficient.

Pumps

The pump is the core equipment that provides pressure to the water purifier system. Common pump types include booster pumps and circulation pumps. The service life of a pump is usually 5 to 10 years, depending on its manufacturing quality and the environment in which it is used. High-quality pumps can be used for up to 10 years under stable working conditions. However, if the pump is often working under high load or the influent water contains a lot of impurities, the life of the pump will be greatly shortened.

Pressure gauges

The pressure gauge is used to monitor the pressure in the water purification system to ensure that the system operates within the appropriate pressure range. The service life of the pressure gauge is usually 5 to 10 years, but due to its simple construction, it usually has the longest service life in the entire system. Unless there is a mechanical failure or abnormal reading, the pressure gauge generally does not need to be replaced frequently.

Controllers

The controller is responsible for managing and regulating the operation of the water purifier, including starting, stopping and monitoring various operations. The service life of the controller is usually 7 to 10 years, but it is also a more complex and prone to failure in the system. The life of the controller is closely related to the quality of its internal electronic components and is usually affected by the operating environment (such as temperature and humidity).

Water storage tanks

Water storage tanks are used to store purified water. The service life of a water storage tank is usually 10 to 15 years, depending on its material and maintenance. Stainless steel water storage tanks usually have a longer life, while plastic water storage tanks may need to be replaced more frequently due to aging of the material.

Piping system

The piping system is a key part that connects various components and is usually made of PVC, stainless steel or copper. The service life of the pipe is usually 10 to 15 years, but it will be affected by the water quality and the environment in which it is used. If there is sediment or scaling in the pipe, it may need to be replaced earlier.

Which part has the highest maintenance cost?

Among the various parts of an industrial water purifier, the most expensive to maintain are usually the reverse osmosis membrane and pump. The following is a detailed analysis of the maintenance costs of these parts:

Reverse Osmosis Membrane (RO Membrane)

The reverse osmosis membrane is one of the most expensive parts in an industrial water purifier. Although its service life is usually 2 to 3 years, the cost of RO membranes is relatively high, and the replacement cost usually occupies a considerable part of the overall system maintenance budget.

Reasons for maintenance costs:

● Membrane contamination: Organic matter, rust, calcium and magnesium ions in the water will deposit on the membrane surface, causing membrane contamination and reducing its efficiency. Although the service life of the membrane can be extended by regular cleaning, the cleaning process itself will also incur certain costs.

● Improper pretreatment: If the pretreatment system (such as activated carbon filter or PP filter) fails to effectively filter out most of the impurities in the water, the RO membrane will be more easily damaged and need to be replaced in advance.

● Replacement cost: Depending on the specifications and quality of the membrane, the price of a single RO membrane ranges from hundreds to thousands of dollars. For large industrial water purification systems, the number of membranes that need to be replaced is large, and the overall cost is high.

Pump

The pump is another part with high maintenance costs, especially the booster pump and the circulation pump.

Reasons for maintenance costs:

● High-load operation: When the pump is working under high load, the wear of mechanical parts is aggravated, which may cause damage to seals, bearings and motors, and needs to be checked and replaced regularly.

● Repair and replacement: The repair of the pump requires professional technicians, and the repair cost is high. When the pump is seriously damaged, the cost of replacing a new pump is even more significant. High-quality industrial pumps often cost between a few hundred and a few thousand dollars, plus installation and commissioning costs, the overall maintenance cost is quite high.

How to extend the service life of parts?

Although the parts of industrial water purifiers have their expected service life, through proper maintenance and care, the life of these parts can be significantly extended, and the replacement frequency and maintenance cost can be reduced. The filter element is the first line of defense to protect other key parts such as RO membranes and pumps. Regularly replacing the filter element to ensure its filtration efficiency can greatly reduce the contamination and damage to the RO membrane and pump.

Although the service life of RO membranes is limited, their service life can be extended by regular cleaning. When cleaning, special cleaning agents should be used to avoid damaging the membrane material. In addition, pumps and controllers are the core of the mechanical and electrical parts of the system. Regular inspection of these components and timely replacement of damaged components can prevent major failures and reduce maintenance costs.

Secondly, excessive pressure fluctuations can cause damage to the pumps and pipes in the system. Using a stable power supply and a suitable pressure regulator to ensure that the system operates at a stable pressure can extend the service life of pumps and pipes. Finally, in hard water areas, scale is one of the main causes of equipment damage. Regular use of softeners or installation of a water softening system can effectively prevent the deposition of scale in pipes and water storage tanks and extend the life of these components.

Kedua, fluktuasi tekanan yang berlebihan dapat menyebabkan kerusakan pada pompa dan pipa dalam sistem. Menggunakan catu daya yang stabil dan pengatur tekanan yang sesuai untuk memastikan bahwa sistem beroperasi pada tekanan yang stabil dapat memperpanjang masa pakai pompa dan pipa. Terakhir, di daerah dengan air sadah, kerak merupakan salah satu penyebab utama kerusakan peralatan. Penggunaan pelembut air secara teratur atau pemasangan sistem pelembut air secara efektif dapat mencegah pengendapan kerak dalam pipa dan tangki penyimpanan air serta memperpanjang masa pakai komponen-komponen ini.